Thanks to anyone who is still keeping up with our blog! You are commended for your loyalty and persistence. We have done a pitiful job at keeping you all up to date on our progress. But fortunately, we have made quite a bit of progress since our last update in July!

Of course, as some of you may know, Mark and Alex originally intended to complete the project and return to the States sometime between October and December of 2013. However, that has changed in the past few months as it became apparent that more time was needed to see the project through to completion. The good news is that we were approved for funding for the remainder of the project. The other good news is that PPB has offered to send Mark and Alex back to Malawi after the Holiday season - when they will return home to see friends and family - to finish the project.

We have continued to work with the site manager (Magombo) and site foreman (Nelson) we hired back in July and have been very pleased with their work ethic and progress. Moving back the finish date (which is now set for March 2014) is not for lack of trying; rather, the size of the project has dictated the completion schedule.

We have completed the main structure - foundation, beams/columns, walls and roof. What remains are the finishes, plumbing/electrical, and the office building. The impending rainy season has affected our schedule as over the past few weeks we were forced to focus our site crew on external works such as drainage ditches and driving surfaces in order to avoid the work site turning into a mud pit from December through March. However, the past week we were able to refocus the work crew on finishing the interior of the factory building and made significant progress in that regard.

There is still much to do before Mark and Alex return home on December 22. Needless to say, the first 3 weeks of December will be jammed pack!

On July 12, after 10 straight 10+ hour days for us (and even longer for our builders), we finished the reinforced concrete slab. This was a joyous occasion not only because it marked the end of the substructure, but also because it marked the end of having to work with Madzi Building Contractors. Despite our differences the contract came to an end amicably and we went our separate ways.

That weekend we headed to Mount Mulanje with the other four Kabula Hill residents - Julie, Christy, Lauren and Cherise - and met up with some Peace Corps volunteers for the Porter's Race. Alex and six of the PCV's decided to take on the 25 km (15.5 mile) 4,500 ft. climb up, across and back down the elevated Mulanje plateau. Needless to say none of us finished anywhere close to the winner who completed the race in just over 2 hours!

Last Monday, July 15, we began a new labor arrangement on site with Symon Mogombo, our electrician, as site manager and Nelson Chipula, a fuzzy gray-haired 70-some year old Malawian, as site foreman. We expected an adjustment period of about 2 weeks but were pleased to discover that after just a few days things were running much smoother on site. Both Nelson and Magombo share our desire for efficiency, organization and quality workmanship.

The column work on the factory was going smoothly enough that on Thursday of last week we began digging the foundation for the 200 sq. m (2,150 sq. ft) office building about a month ahead of schedule.

With things running the way they are currently we find ourselves with some free time that we're not quite sure what to do with. Unfortunately it has been rather cool lately, as low as mid-40s at night and mid-60s during the day, which is pretty cold when you live in a concrete structure with no insulation! And as a result we haven't been very motivated to recreate outdoors. We have started playing some Settlers of Catan, however, which Julie brought with her from the States.

We've made plenty of progress over the past 2 months, and this week we are making final preparations for the slab which is arguably our single biggest undertaking of the entire project. The roof truss fabrication and installation is another large aspect of the building, but just last week we contracted that out and won't be very involved with the work itself. The 15cm thick slab, on the other hand, has involved countless hours of preparation and will involve significant oversight while it is being poured. The reinforced slab will cover an area of approximately 1,200 square meters, which means we will need to mix about 180 cubic meters of concrete with our 2 mixers. A cement truck would come in real handy right about now!

The past couple months has seen Mark and Alex splitting up on a daily basis to cover the many tasks. We often use lunch as a time to catch up on the day's work. Fortunately, the District Council and Traditional Authority have not bothered us. Let's hope that remains the case for the rest of construction.

Some other developments on site over the past couple months include: finishing the perimeter fence and installing gates, connection to power supply, drilling a borehole for a clean water supply, setting up security lights around the property, pouring the footing, laying the foundation walls, pouring column bases, pouring columns up to slab level, backfilling, and storm water drainage.

Unfortunately, things have not gone the best with our contractor, Madzi Building Contractors. We have very different ideas about workmanship and labor force size. Fortunately, we only signed a contract through the completion of the substructure. So once the slab is finished we look forward to changing our labor arrangement and taking more control of the labor force. We plan to appoint our electrician, Simon Magumbo, as the site manager. He has been a great person and friend to work with over the past several months and his many connections and insights have made our job much easier. We quickly discovered that his expertise extends well beyond electrical work.

After much planning, emailing, more planning, learning, talks with contractors and procuring supplies we have finally begun physical work on the actual factory structure. About a week ago we began excavations, which here means about 50-70 men digging trenches for the footing with hand tools.

The past week has seen Mark out at site more as the head supervisor of the entire operation as Alex works primarily at buying and procuring building supplies - cement, rebar, electrical equipment (including a 200 kVa transformer) and more. The digging and leveling is still and progress and we hope to start pouring concrete for the footing and vertical columns by the end of this week.

Overall, we are pleased with how things are moving along. We chose a new contractor for the building and we are feeling out our new working relationship. It is taking some time and patience to adjust.

It certainly feels good to finally see progress on the factory building itself. We hope to see some reb

A couple weekends ago we (Julie, Mark and Alex) made a trip to the Mulanje Massif - a monadnock that juts up 6,000 ft out of the surrounding flatland. The raised plateau is about 210 square miles and hosts several granite peaks, the highest of which is 9,900 feet. It is quite spectacular.

We hiked with our guide, George, and our porter, Moota, to a hut that overlooks Chambe Peak. There are about 10 huts up on the massif open to any willing hikers.

We're sure this trip to Mulanje won't we our last! Enjoy the photos...

Since the shutdown by the D.C. construction has been moving along at a rapid pace. Our fence is around 50% complete and at this rate should be complete in the next 2-3 weeks. Pretty amazing considering the fence is solid brick, 3 meters tall (one meter underground) with a concrete footing and 500 meters in length! To get an idea of why things have been moving along so quickly, with virtually no machinery, you only have to look as far as our time sheet. Last week we had 80 people working on site, from our contractor and his foreman all the way down to men wheeling wheelbarrows and women carrying water. Our contractor, Mr. Luphale, has been very patient and flexible through all of the delays and frustrations that we have experienced recently which we have greatly appreciated.

Along with the fence making great progress we have also finished the plans for the factory building and are getting ready to break ground within the next 2 weeks. Currently we are asking for quotes from several different contractors and should have a decision made by the end of this week. We are both very anxious and excited to get started seeing as we have been here 2 months now and still do not have a hole in the ground.

Aside from work we have been able to do a little traveling, most recently we took a trip to Lake Malawi. If you have never heard of Lake Malawi I would suggest checking out it's Wikipedia page. It is quite the amazing place, lush hillsides plunging into the beautiful blue water of Lake Malawi. We stayed in the small fishing village of Cape Maclear which is on the very southern tip of the lake. The village has a very laid back attitude, much like that of the Caribbean. Along with us on the trip were Julie and Christina, two of the other PPB volunteers that we live with at Kabula Hill. While at the lake we were able to do some snorkeling, swimming, and a lot of relaxing. The snorkeling is pretty amazing especially when you consider that it is a freshwater lake. Lake Malawi is home to the most fish species (known for the colorful cichlid species) of any lake in the world! We both agree that there will be many more trips to the lake in the time that we have left in Malawi.

Looking forward to the next few weeks we are hoping to finish up the fence and begin foundation work on the factory. We're hoping that it will be smooth sailing from here on out but if there is one thing that we have learned in our first 2 months in Malawi it is that delays are inevitable, our goal is to minimize the amount of them.

Unfortunately, since our last post not much has happened in terms of building. We restarted construction of the perimeter fence and completed the storage shed but were then shut down again by the District Council last Wednesday. The reason was unclear as we have received permission from other agencies, and ultimately we figure they are simply puffing their feathers hoping to get something out of us. It's all quite frustrating but seems to be the reality of building here.

In the meantime we've continued to push along our architect in hopes of finally having detailed building plans in our hands. He most recently told us that we should have them by next Tuesday, March 19. A lot is waiting on those plans, like getting quotes from building contractors for construction of the factory and developing an electrical and water/plumbing plan. Yesterday we received word that we could restart construction so the fence is back underway...for now. We also received word that the main cement manufacturer here is shutting down production for 2 weeks, so we're making sure we have a decent stockpile of cement in case 2 weeks turns into a month. As of right now we hope to start pouring the factory foundation by April 15. The betting books are open for over/under bids.

But enough about the building - especially as there isn't much that's new. We figure some of you may be curious about what we experience day to day outside of our job. We live on a property owned by an Indian man and his son - Tochi and Tinu. Together they run a paint business called Monolux Paints. Right now there are 5 other girls living there with us - Claire, Betel, Taylor, Julie and Christina. The 7 of us are split between two houses - Up house and Middle house. Down house has seen better days and is currently under renovation. We have electricity about 95% of the time and water about 70%, however Middle house has a holding tank so we have some reserve when the water is out. The houses are quite nice by Malawian standards and we are fortunate to live in such a nice area.

Claire and Betel have been here for about 6 or 7 months while Taylor and Julie arrived with us. All 4 of them will leave around May 1. Christina arrived on March 2 and will be here until June 1. All the girls are here through the Saint Louis Nutrition Project (SLNP), the organization that technically runs the clinics. (Project Peanut Butter is primarily involved with the production of chiponde, not the distribution of it or running clinics). They divide up about 5 or 6 clinics a week between them. They leave at 5:30am with a driver and nurses and drive anywhere from 45 mins. to 3 hours to the various clinic sites. We usually leave for work around 7:30 or 8:00am, so in general things end pretty early during the week at Kabula Hill.

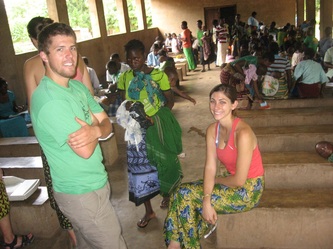

This past Monday, March 11, we took advantage of our lull in construction to join the girls for a clinic. Betel and Claire are traveling in Zambia right now so we essentially took their place. It was a nice change of pace and great to see the countryside and villages. The area we went to is called Chikwawa, and even though it's only about an hour or two away, it is about 3,000 feet lower in elevation and considerably warmer. We helped when we could but were mostly assumed the role of photographers. Alex brought his soccer ball and kicked around with some of the grade school kids as the clinic was winding down.

Next weekend we plan to head to Lake Malawi with Taylor, Julie and Christina for some relaxation. We have reservations at a hostel/lodge right on the lakeshore in a town called Cape Maclear. We look forward to seeing more of Malawi.

We can assure you that a change of pace the past 10 days did not mean we were just sitting around. We began the process of applying for water and electric, purchasing a used 20ft. shipping container to secure our equipment on site, purchased a 3-ton truck for hauling materials, met with our architect to finalize layout and much more. It was nice to not have to manage the construction on site everyday, but now we are back at it.

After much driving to track down the TA, numerous visits to government offices, and an impromptu speech at a village meeting we were finally given the 'OK' to continue building our perimeter fence and finishing up the storage shed. A recent strike by most government employees certainly hasn't sped things along, and it has us a bit concerned about the potential for more delays in the near future...but that's building in Malawi.

Dr. Manary arrived on Saturday (Feb. 16). His presence has helped to push things along, but it has also kept us on our toes. Often casual evening conversations at Kabula Hill (where we live) turn into work meetings as we discuss the project, vehicle and house maintenance, and how things get done in Malawi. Of course we are grateful for the tips and advice he sends our way.

There's not too much more to report at this time. We are off to facilitate the delivery and placement of our shipping container. If you have specific questions feel free to post them on the comments and we will do our best to respond. I'm sure we don't cover everything in these posts that people may be curious about, so feel free to ask anything or request certain photos. For us things have begun to feel routine, so we may overlook certain aspects of our experience that you would find interesting.

**Please bare with us as we figure out how to create blog posts that allow people to comment. I think from now on we will try to post on the "Blog" tab of our site.

Friday offered our first, and most certainly not last, setback with regards to construcion. As I'm sure is the case in many African countries, Malawi has municipal government alongside a more traditional system of chiefs. While we have the legal right to build a production facility on the plot of land we own near Lunzu, our contacts here in Blantyre advise that we also receive permission from the Traditional Authority (TA). On Friday we went to meet with the TA along with Lynda (production manager at current factory) and our supply shed/fence contractor Mr. Luphale. We were told to wait in the car for fear that our white skin would result in the TA asking for more money from us. Unlike most permits and licenses which have a set fee, receiving the blessing of the TA requires a negotiable sum of money. We've heard that we may be asked to pay between K6,000 and K15,000 (which is roughly $16.50 - $41.50) when all is said and done.

Apparently the TA had some concerns about our factory, like pollution and location compared to other factories nearby. Of course chiponde production doesn't produce much pollution, but you can't argue with the TA. The TA asked that we stop any further construction until he meets with the District Council this coming week to sort the matter. We've been told that by Friday at the latest we should get the go ahead. Of course this being Malawi, we aren't getting our hopes up.

After our meeting we returned to the building site to inform the 50+ builders and casual laborers currently working for us of the news. They were understandably dismayed at the prospect of a week without work but we made sure to pay them for the weeks worth of work.

While we certainly hope the delay won't last too long, the hold allows us to catch our breath a bit. We still have plenty of other things we can work on - finalizing the building layout, figuring out transport and security of our newly purchased concrete mixer and vibrator, making additional connections, etc.

Enjoy the photos! Soon we'll try to post more than just building site pics.

|

RSS Feed

RSS Feed